In breweries, it is important to either kill off microorganisms (MO) that may pose a threat to drinking and process water, air and product or transform them into a state in which they cannot propagate at all or to a degree that can be tolerated. This contribution describes the disinfectants that can be used and how problem definition and task, water quality and disinfection processes can be reconciled.

This series of contributions will identify the reasons for inadequate yield of bitter substances when using conventional brewing processes. The various mechanisms that come into play, necessary for transferring bitter substances from hops to finished beer, are discussed separately to start with (see part 1 and part 2). This third part deals with possible adsorption of bitter substances as well as evaporation of same. With equipment described in the fourth part, something that can be retrofitted easily, it is possible to considerably reduce consumption of hops in beer brewing, while complying with the German Purity Law. Resulting savings are very considerable.

Mettler Toledo Safeline has made a significant breakthrough in the detection of contaminants in fluids with the launch of the new FluidCheK x-ray inspection system. Developed primarily to meet the needs of manufacturers and packers of beverages and other liquids, this efficient system is equipped with advanced image-scanning software and employs x-ray beams at an angle for total quality control.

Thermo Fisher Scientific Inc. announced the launch of the Thermo Scientific EQuan MAX, an automated high throughput Liquid Chromatography-Mass Spectrometry (LC-MS) solution for the analysis of contaminants in water and beverages. This innovative system with high resolution and accurate mass (HRAM) boasts new screening and quantitative capabilities that provide enhanced system flexibility and productivity.

This new development was intended to take the place of the successful and internationally established first dTRANS …01 series. With extended functions in the same compact housing, the JUMO dTRANS pH/CR/AS/Ci 02 instrument series now covers all the measurement variables. The mounting dimensions for the panel-mounting instruments are 96 mm x 48 mm x 90 mm (W x H x D) and these instruments are also available in a surface-mounted housing, with IP 67 protection.

GEMÜ has developed new stainless steel ball valves in the nominal sizes DN 8 – 100. The new GEMÜ 740 series has been specially designed for demanding applications in the pharmaceutical and foodstuff industry.

Baumer’s digital pressure switch series TED is now available with several 3A-approved process connections. Therefore, the hygienic measuring instrument is especially suitable for applications in the food and beverage and pharmaceutical industries.

Bürkert Fluid Control Systems has enhanced the technical features and appearance of its digital flow transmitters. The models 8026, 8036 and 8076 now shine in the consistent stainless steel design of the ELEMENT series. New processors, new software, additional features and an innovative operating concept distinguish the next generation of these successful Bürkert transmitters.

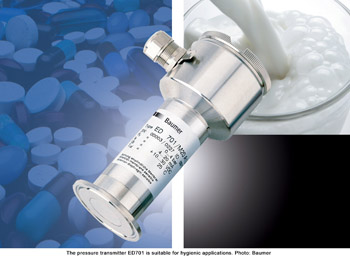

For hygienic pressure measurement, Baumer offers the electrical pressure transmitter ED701. It is especially suitable for applications in the pharmaceutical and food & beverage industries as well as in medical technology. The measuring device features high accuracy and long-term stability. It is available with several Clamp and hygienic process connections.

Kvass or kvas, is a traditional beverage primarily known in Russia, the Baltic States and the Ukraine, where it is predominantly consumed during the summer months. The ingredients and recipes are diverse, because kvass production was for centuries a cottage industry; that is, it was brewed by families at home. Each family possessed their own recipe for brewing kvass using a wide range of ingredients; however, one ingredient common to all of them is rye. For kvass made at home, the rye was first baked into loaves of bread before commencing the brewing process [1]. For industrial production, it was necessary to find other raw materials, such as raw grain, sugar and various types of malt. The following report offers an overview of the ingredients and processes and also outlines the possible methods by which kvass can be produced on an industrial scale.

With the InPro 6970i series, Mettler-Toledo Ingold introduced a new line of optical sensors for the measurement of dissolved oxygen in Food & Beverage. Based on a chemo-optical technology, the InPro 6970i sensor offers significant advantages for the brewing industry. High operational availability, combined with excellent measurement quality is the perfect answer to the most demanding brewery requirements such as increased product yield and guaranteed minimized level of oxygen in beer.