Non/Low-alcoholic beverages

Tate & Lyle has entered into a five-year strategic partnership agreement with New Zealand-based BioVittoria for the exclusive global marketing and distribution rights for BioVittoria’s monk fruit. The only fruit-based calorie-free sweetening ingredient available today, natural monk fruit extract is a means to reduce sugar and calories in foods and beverages.

Non/Low-alcoholic beverages

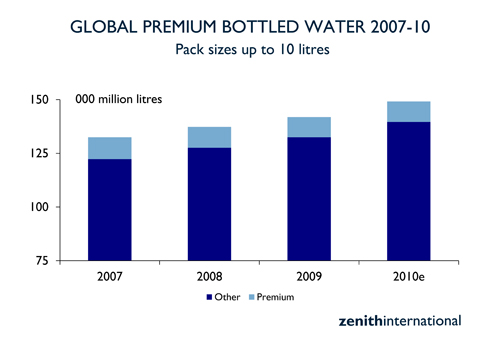

As Zenith international reported in March 2011, the global sales of premium bottled water rose from 9.4 billion litres in 2009 to 9.5 billion litres in 2010. This represents 6.3 percent of all bottled water consumption in pack sizes up to 10 litres.

Non/Low-alcoholic beverages

Premium quality, indulgence, mouthfeel and texture through fruit pieces and fruit cells are key priorities in this region’s beverages. Drinks tend to be overtly sweet, with typical sugar levels in the range of 12-16 percent. Carbonated soft drinks are the most popular category followed by fruit drinks with fruit pieces and cells.

Filling

KHS has developed a completely new concept for filling non-alcoholic beverages in plastic bottles. This is in the form of a package concept consisting of rinser, filler and closer unit. The system is already configured to handle very diverse plastic bottle sizes. Starting with 0.25 I and going up to 3.0 l, filling capacity ranges from 9,000 to 60,000 plastic bottles per hour. The concept makes it unnecessary to have a classical pre-filler table. All elements previously integrated in the pre-filler table are now part of the modern filler design. Screw conveyors are no longer required. After the infeed starwheel, a feed plate takes over conveying of the PET bottles in the direction of the rinser. The same principle applies to the exit of the PET bottles from the closer area. ...

Non/Low-alcoholic beverages

Blending equipment for production of non-alcoholic beverages is experiencing a shift away from mechanical solutions to automatic plants. This results from the major trend towards greater automation and flexibility.

In view of the increase in product variety in the area of mixed beverages, new standards have to be also met in production of beverages, e.g. tight tolerances as far as Brix and CO2 values are concerned, a low O2 content as well as minimum losses of product and syrup.

Non/Low-alcoholic beverages

Creative and innovative beer combinations with non-alcoholic beverages make modern beer mix beverages an innovative product segment in Germany. Based on a long tradition, beer lends itself as a base for new and modern mixed beverages – for example shandy or cola beer- and offers attractive growth potential for German breweries.

The beer market in Germany and almost all the countries of Western Europe is marked by a downward trend in the consumption of beer. In addition there is a great deal of pressure from the concentration of the trade and certain sectors of it. This situation will not improve in the near future but, rather, will intensify. New strategies are needed, together with new products and services.g. herbs, vitamins, taste components, alcohol content, etc.

Non/Low-alcoholic beverages

This paper covers U.S. American and Canadian non-alcoholic (NA) malt beverages tested in our Weihenstephan Institute between 1980 and 1997. It is well known that the term "non-alcoholic" is not allowed in these two countries. The maximum permissible alcohol level in NA malt beverages is 0.5 vol.%.

Non/Low-alcoholic beverages

This article describes new industrial production concepts for non-alcoholic malt-based beverages/functional drinks for the international beverage industry. These open up new possibilities for utilising existing production capacities in breweries.

Beer consumption continues to drop, the tendency is increasingly towards "non-alcoholic". In the wake of the big success of traditional beer-based beverages such as shandy, an obvious move was to mix non-alcoholic beer with soft drink components in order to sell it opportunely, as e.g. "non-alcoholic shandy" or also as an isotonic thirst quencher.

Non/Low-alcoholic beverages

The continuous process monitoring in the production of sugar-free soft drinks demands considerably more of measuring systems than is the case with sugared drinks. Digital density measurement in combination with rapid, high-precision temperature and CO2 measurement has proven to be a robust and highly accurate method for the process control of sugar-free and sugared soft drinks.

Non/Low-alcoholic beverages

Coca-Cola HBC (CCHBC), the world’s second largest Coke bottler, reported consolidated nine months net profits of 38.5 million Euro against a break-even position last year. Sales were up 12 percent to 2.69 billion Euro.