General information | From the multiplicity of pump types, pumps should always be selected so that they are optimally suited to the particular case. In this final part of the pump series, Dr. Hans-J. Manger presents the most important criteria to be considered when selecting pumps.

Young, creative and ambitious | It all began in Australia. While in Melbourne for business, the then 18-year-old Roel Buckens discovered he had a passion for brewing. Back in the Netherlands, he started his first brewing experiments, and in 2015 he then opened the Frontaal Brewing Company in Breda. His creative beers obviously hit a nerve. Thanks to several crowdfunding campaigns, the brewery has steadily grown ever since. Frontaal recently invested in a completely new brewing plant at its new location, “The Bay”. The project was realised together with Rolec GmbH, a German specialist for process and brewery technology from Chieming in Upper Bavaria.

Mash filtration | Productivity of a brewery may be considerably compromised by lautering performance. In order to counteract inefficiencies and accelerate the process, a new process strategy was investigated in the context of a research project at the Department of Process Systems Engineering. In a two-part article, we will present the theoretical approach, use of packing and its application in a practical test on a laboratory scale.

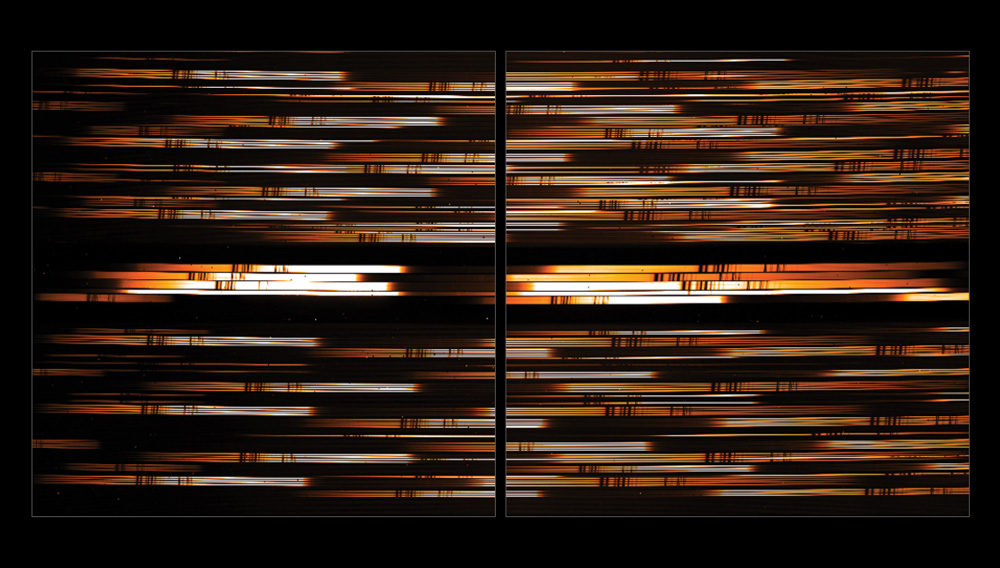

Data analysis | Increasing digitalisation makes it possible to collect and analyse copious amounts of data with multivariate cause-and-effect relationships. However, brewery operations face major challenges when attempting implementation on their own. This contribution presents findings and solution pattern from the research project “Data-driven Process Optimisation using Machine Learning in the Beverage Industry” (DaPro).

Digital transformation | The construction of a new production facility poses increasingly greater challenges for the international brewing and beverage industry. To name just a few factors: Its flexibility must be ever greater, it must consume fewer and fewer resources and raw materials and its time to market must be as short as possible. Against this background, Ziemann Holvrieka GmbH is breaking new ground in the realization of a turnkey project. In this case, standardization and digitalization are of central importance.

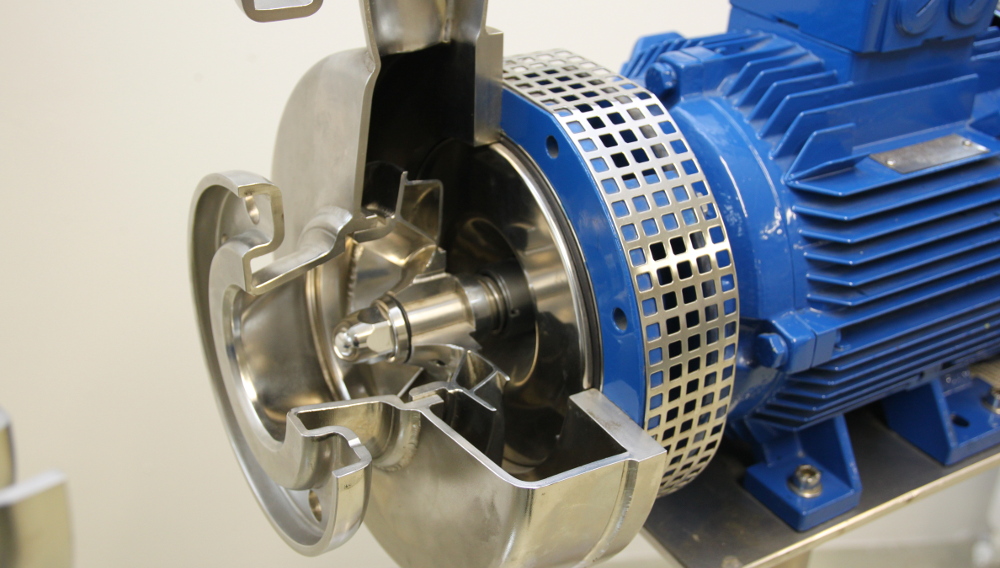

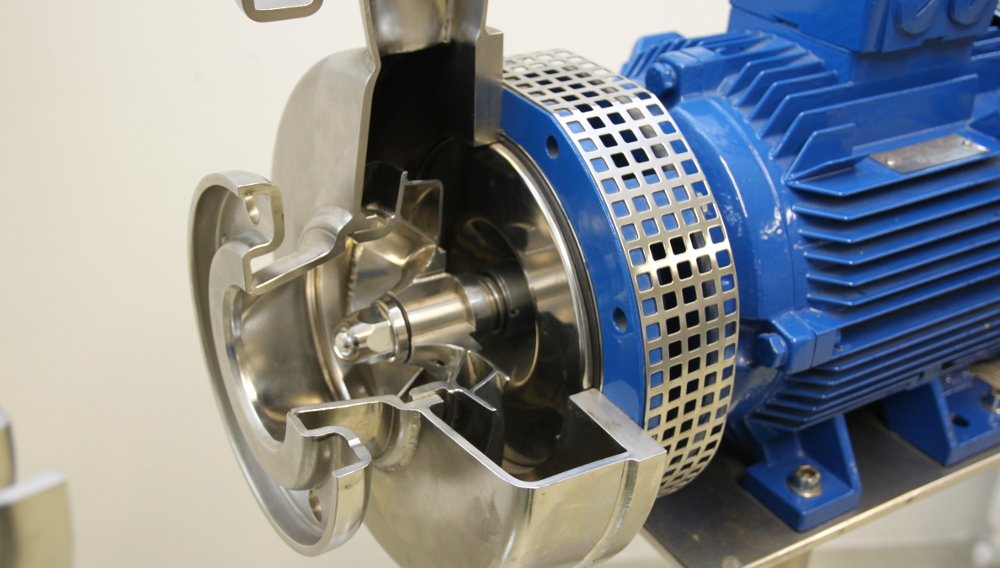

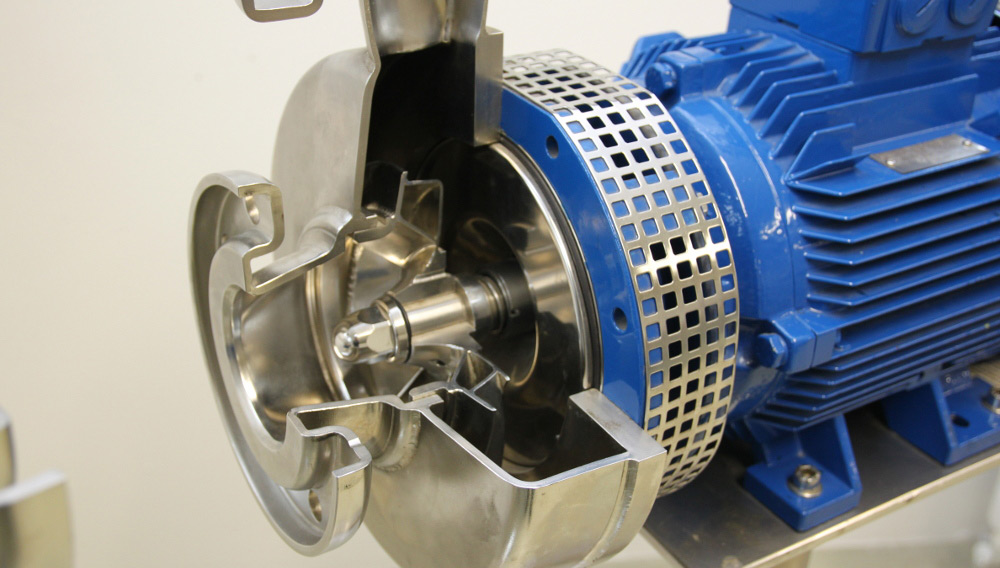

Optimum operating point | The seventh part of our pump series deals with the performance of pumps. When sizing a pump, the delivery rate anticipated as well as pressure to be handled have to be considered and adjusted to pump conditions. In this way, the plant designer can select a pump having optimal hydraulic efficiency. The pump characteristic curve and possibilities to influence same are essential parameters in this instance.

Unique sensory profile | Strongly brewed, malty monastery beers inspire beer lovers. According to traditional recipes, the monks use caramel malt and add liquid rock candy (sugar candy) to the wort. Due to the addition of sugar, these beers reach a high alcohol content. Caramel sugar syrups combine the sensory benefits of liquid rock candy and caramel malt. The authors from Anhalt University examined the use of caramel sugar with regard to a well-rounded beer flavor profile and the physico-chemical beer stability as well as beer color and haze.

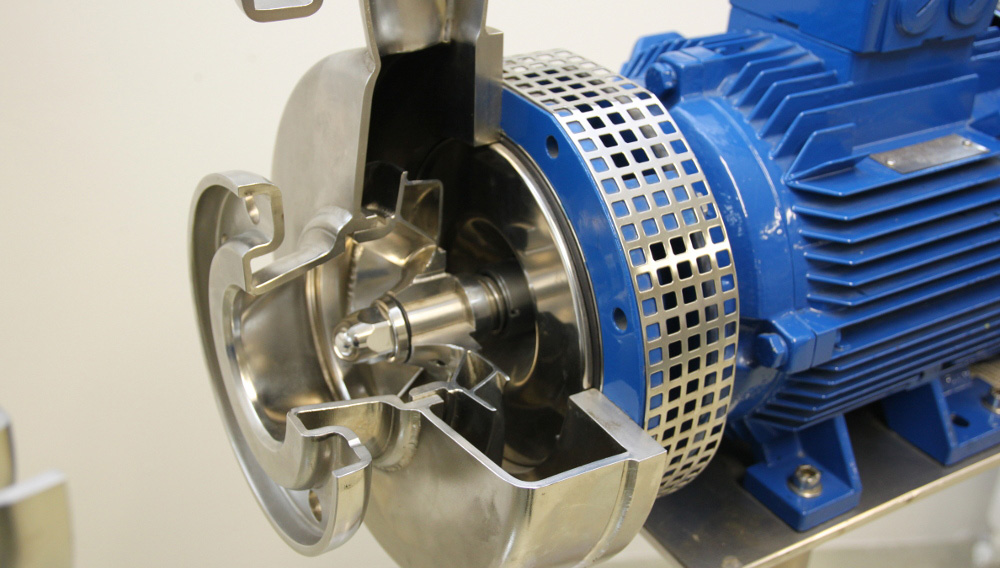

Special applications | Centrifugal pumps play a central role in breweries when it comes to pumping media such as beer and water. However, for other tasks, pumps are used e.g. for evacuation in bottle filling or for compression in hydraulic units. This sixth part of our comprehensive series on pumps deals with these types of pumps.

HOP ADDITION | Does first wort hopping during lautering have a positive influence on the yield of bitter substances and on the beer quality? What kinds of results are currently possible through the use of hop pellets? The authors analyzed nine beers from brewing trials for bitter substances, aroma compounds, sensory attributes and aging indicators.

Accurate dosing | Part 5 of the pump series of articles describes a specific task of pumps. Dosing pumps are used for accurate dosing of cleaning chemicals, water treatment, beverage mixing and filter aids and stabilisers.

Best of two worlds | The historical region of Tyrol, now divided between Austria and Italy, is located in the eastern part of the Alps. The people of the Italian South Tyrol speak German, but identify themselves primarily with the culture of winemaking, not brewing. We talked about the position of brewing in modern South Tyrol with Gerhard Sanin, a winemaker and brewer who heads the Weingut Moser winery and the Mendelbier brewery located under the same roof.