Plug-and-Run for AirCo air conveyors

Clients want to see minimised erection times for their air conveyors.

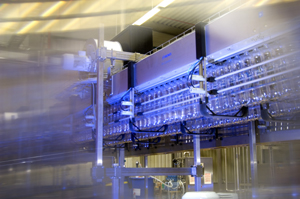

Krones AG, Neutraubling, Germany, has accordingly developed the Plug-and-Run system for its AirCo air conveyors. The pneumatic components are complete with fully assembled hosing, and the shaft supports have been mounted. Neck-ring guides and rails have been set to the range of containers involved. Pressure and function tests have already been performed in the factory. Functional reliability at commissioning in the client’s facility is assured.

The new holistic concept, significantly outperforming other manufacturers in terms of cutting installation, maintenance and expansion costs, saves time, saves money, and reduces possible sources of malfunctions. The air conveyor segments, completely assembled in the factory, are erected and commissioned at the client’s facility in a minimised timeframe.

The AirCo air conveyors can be mounted on the wall, suspended from the ceiling, or erected on the floor with supports. The floor-mounted configuration is designed to handle elevations of up to 4.5 metres.

AirCo air conveyors score in terms of process-optimised control technology. All drives are frequency-controlled. The radial fans are energy-economical and quiet in operation. AirCo air conveyors are made of stainless steel throughout. They offer minimised make-ready times for changing over to different products. Optimised individual components mean that complex PET bottles can be reliably handled.