Sufficient supply expected | Quality differences characterize this year's spring barley harvest in Europe. Protein content and screening vary greatly from region to region.

The hopping method matters | Along with yeast, hops provide some of the key volatile compounds involved in beer typicality. This is the reason why the choice of hop variety has a major influence on beer aroma profile. As hopping methods also play an important role, this study was aimed at identifying the impact of three hopping methods, using the Alsatian Barbe Rouge hops, on the sensory and analytical properties of beers. When dry hopping beers, the level of odour-active compounds was higher than that of the other ones. Five compounds linked to red fruit and strawberry-like aromas were identified: ethyl isobutanoate, ethyl butanoate, ethyl 2-methylbutanoate, 3-methylbutyl-2-methylpropanoate and 2-phenethyl hexanoate.

Mollier diagram | Energy input in the form of electricity and heat represents the major cost factor in the malting process – roughly 40 % of total production costs and more than 60 % of variable costs. It comes as no surprise that the malting industry has successfully focused on the issue of energy for decades and that saving potentials are largely exhausted. When further optimisation potentials will have been identified, it will be necessary to have a highly developed technological and technical understanding and a love for details.

Newsletter, October 2019 | The demand for a very easy-flowing CO2-Extract which flows well enough to be dosed at low temperatures has now been met by the creation of our Hopsteiner HopFlow.

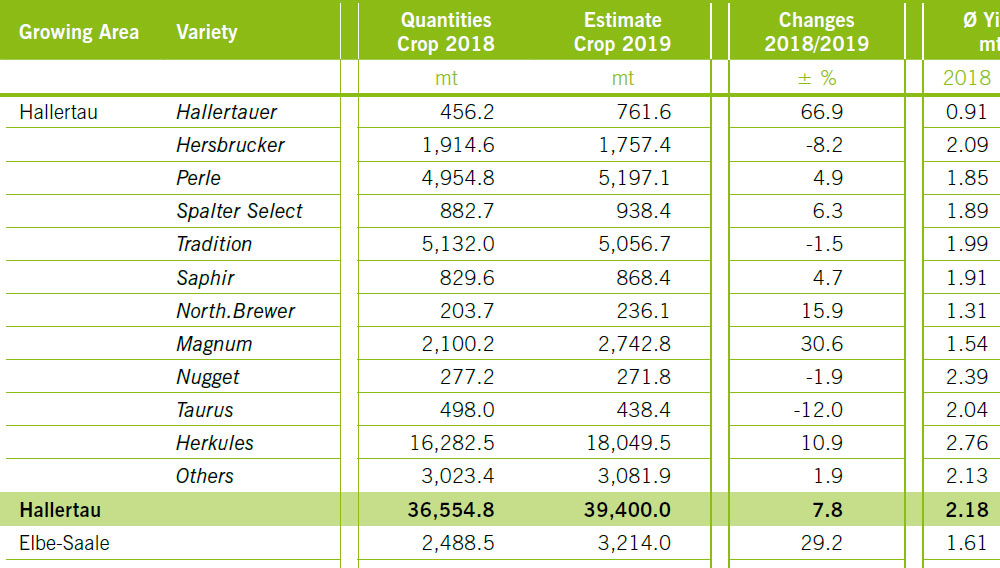

Hop market | The crop estimate for the Hallertau was announced on August 21st, meaning that crop 2019 estimates have now been submitted for all German hop growing areas.

Hop naming | Who would not know the sender-receiver communication model? In case of a “fault in the channel”, transmission errors occur in communication. BRAUWELT International author Horst Dornbusch observes something similar with regard to the newer German Flavour Hopfen varieties like Mandarina Bavaria, which fail to meet the expected resounding success among craft brewers in the North American target market. Read more about what slows down commercialization and makes for confusion ...

On a smaller acreage a good average crop of spring barley is currently growing in many European countries. The growth conditions were good in many regions, even with drought and sometimes too much rain. From today's perspective, a good proportion of malting barley is expected.

Loss processes | The aroma spectrum of hop raw material generally differs considerably from the aroma that it introduces into beer. Apart from conversion reactions of volatile hop compounds, this is due to losses of same during the brewing processes. The decrease in concentration of specific substances during fermentation is steep, but can be influenced.

High-alpha hops | Herkules is a high-alpha variety bred in Germany and, with 4584 ha (2016) under cultivation, it accounts for the largest growing area in Germany. Within just a few years, it overtook the two varieties, Magnum and Taurus, by a large margin. In 2012, Polaris got the official registration as “Special Flavour Hops” on account of its specific aroma impression. It is grown on 106 ha (2016) in the Hallertau and the Elbe-Saale region. This article deals with the differences between the two varieties from the above-mentioned growing regions. Six brews were produced in order to describe them in the course of the brewing process.

Wort analyses | The new brewhouse concept Omnium by Ziemann attracted great interest among experts and practitioners after being unveiled at BrauBeviale 2016 and drinktec 2017. Reactions ranged from sheer surprise to anticipated criticism. The results of this interdisciplinary research and development project are derived from many tests from pilot to industrial scale from 10 to 140 hl [1-5]. First hands-on experience is now available at Schlossbrauerei Reckendorf.

Hop-derived branched-chain esters | Craft beers contain various hop-derived esters, for example isobutyric esters (isobutyl isobutyrate, isoamyl isobutyrate, and 2-methylbutyl isobutyrate) and ethyl esters of branched-chain fatty acids (ethyl isobutyrate, ethyl isovalerate, and ethyl 2-methylbutyrate). Many researchers have reported of various hop-derived esters for a long time. However, the fate of such esters during beer production is not yet sufficiently known. This study proposes a new hypothesis about a possibility of transesterification between several hop-derived branched-chain esters. The following article summarises a part of the research results which have already been published in BrewingScience 71, 2018, issue 6: November/December.