Before industrialisation, kvass was made from rye bread soaked in water and left in a warm place to undergo gentle fermentation. However, use of bread as a raw material for industrial beverage production soon proved to be rather unpractical and uneconomic. More modern production processes became thus increasingly based on beer production processes. This contribution describes a novel process that can retain the characteristic taste of rye bread and bread crust, without major energy losses and without concentrate baking.

Most discussions regarding food and beer pairing emphasize the perfect marriages. It is remarkable to beginning beer enthusiasts how well beer pairs with certain foods. In his preparation in presenting a workshop at Slow Food’s Salone del Gusto in Italy, BA president Charlie Papazian discovered the fascinating dynamics of a fundamental taste called umami.

VTT has examined one of five bottles of beer salvaged last summer by divers from the wreck of a ship that sank an estimated 170 years ago in the Åland Islands (as reported by BRAUWELT International).

When the Weihenstephan Research Center for Brewing and Food Quality, formerly known as the State Brewing Technology Testing and Experimental Station, was established in 2004, this transformation represented only one of the many steps in its long history of continuous development. The new name might garner the most attention, but much has changed in recent years, making it worthwhile to take a closer look behind the venerable façade of the institute facing the Alte Akademie.

The work accomplished by ProLeiT on behalf of Colombia’s Bavaria brewery can be best compared with open heart surgery on a top athlete performing under stress on an ergometer during the intervention. ProLeiT has successfully managed to gradually upgrade this large brewery with an annual production of around 11 million hectoliters, which is currently undergoing a capacity expansion, to the brewmaxx V8 process control system. This modern control system not only reduces the number of isolated solutions and optimizes process sequences, but also enables consistent tracking and tracing on the basis of its integrated MES functionality.

In this two-part article the authors, two teachers at The Scandinavian School of Brewing in Copenhagen and their Diploma Master Brewer Class 2010/2011 present their idea of how the next generation of breweries larger than 200 000 hl/month could look like. In the first part of the series (published in BRAUWELT International No. 2 2011, p. 88 ff.) they introduced the subject, reviewed the developments in brewing over the last 70 years and began to describe the core issues for the future brewing industry, focusing on raw materials, brewhouse, yeast and fermentation. The second part covers the issues stabilisation, filtration, energy and environmental aspects, waste water, storage and packaging.

Many factors have influenced and impacted the beer sector in recent years and decades. Globalisation, economic developments, generation change, changed legislation, a growing (and exaggerated) health consciousness and an increasing trend towards individuality are just some of the reasons why times are long passed when breweries brewed beer exclusively. New target group trends are also presenting equipment suppliers with new challenges, as this series of articles will show, taking as an example the Russian national drink, kvass. Part 1 covers the market situation.

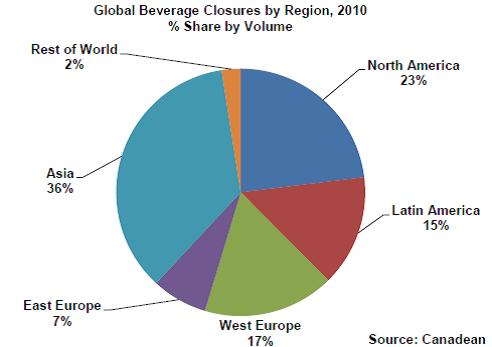

In spite of the economic slowdown in many markets over the last 2 years, beverage closure demand has continued to grow strongly, driven partly by the sustained shift towards pre-packaged beverage consumption in many developing markets. Looking at the global beverage closures market in detail, total demand across the soft drinks, dairy drinks and beer markets under review amounted to around 1055 billion closures in 2010. On a regional basis, Asia already accounts for the largest share of total annual closure volumes at 36 percent, equivalent to around 375 billion units. Collectively, the Americas combine for just under 400 billion, Europe for around 250 billion, the rest of the world around one tenth of that.

The board of directors of the Brewers Association (BA), the trade association representing the majority of U.S. brewing companies, has voted to change the BA’s designation of "small" in its definition of a "craft brewer." The association’s board of directors also has revised its bylaws to reflect the change. In the BA’s craft brewer definition, the term "small" now refers to any independent brewery that produces up to six million barrels of traditional beer. The previous definition capped production at two million barrels.