Malt production in Brazil with technology from Zeppelin Systems

The German Purity Law of 1516 already proves that the mixture of hops, malt, yeast and water guarantees good taste and made beer famous worldwide. This is also the case in Brazil. This is where one of the world's largest green field malt production plants is currently being built. A cooperative made up of several companies, including Cooperativa Agrária, is relying here on the technologies of plant manufacturer Zeppelin Systems, based on the know-how to supply complete plants for malt production for more than one decade.

Brazilian beer consumption is growing by 3.5 percent per year. Yet Brazilian consumers already drink beer brewed from 1,75 million tons of malt per year. Until now, the country has imported more than a half of the barley for malt production from abroad. The rising demand for beer and thus also for malt and barley therefore requires not only the country's own cultivation areas, but also new plants that can convert the mass of malt required. In addition, the drinking behavior of consumers is changing, and they are increasingly preferring beer varieties with one hundred percent malt content. Therefore, in Brazil, the cooperatives Agrária (Guarapuava), Bom Jesus (Lapa), Capal (Arapoti), Castrolanda (Castro), Coopagricola (Ponta Grossa) and Frísia (Carambeí) have joined forces to build the world's largest malting plant ever built in a single project: Maltaria Campos Gerais.

This plant is expected to produce between 700 and 800 tons of malt per day. This corresponds to an annual production of about 240 000 tons of malt and about 14 % of consumer demand. For Agrária, this is the second Zeppelin plant of this kind, but with much higher capacity. The existing plant is reaching its limits due to changing consumer behavior and cannot be expanded because there is no more free agricultural land in the surrounding area. The Maltaria Campos Gerais project is located in an area that has an additional 100,000 hectares of land available for barley cultivation.

Process technology from raw material intake to uprooting

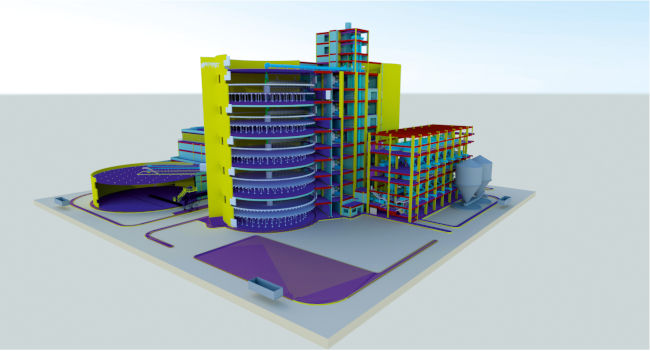

Agrária has already relied on the renowned technologies of this plant manufacturer for the first Zeppelin plant. The quality of the components, the overall concept, and the process engineering design convinced the company, so that they are now placing an order for the large-scale plant with the same supplier. The Maltaria plant in Campos Gerais consists of a steeping building with 24 steeping tanks, two towers with five germination boxes each and two kilns, as well as peripheral equipment. To ensure the high throughputs with consistently high product quality from raw material reception to uprooting, Zeppelin Systems offers various solutions. For example, the bucket elevator ensures gentle, vertical conveying of the barley into the flow weigher. The automatic flow scales from Zeppelin Systems enable precise weighing and the user always has all parameters in view, so that the exact amount of barley is fed into the production process and the steeping process can then begin. Here, the barley is moistened until it begins to germinate.

Germination and kilning - high quality and efficiency thanks to sophisticated technologies

Germination is a fundamental process step in every malting plant. The Maltaria Campos Gerais plant has ten round germination boxes distributed over two 65-meter-high concrete towers, each with a diameter of 30.5 meters and a capacity of 400 tons of barley. This Zeppelin technology ensures the handling of large volumes, which is elementary for Agrária, since the large plant will produce malt 365 days a year. In the germination plant, the barley is continuously moistened by air flowing through and ensuring that the barley does not dry out.

In addition, there are two circular kilns with a diameter of 40 meters and a capacity of 400 tons of barley. The kilns are located in adjacent buildings. When it comes to roasting, Agrária relies on high-performance equipment from Zeppelin Systems - this makes it possible to generate differentiated taste and visual profiles and thus specifically influence the character of the final product. Between the two kilns, a heat recovery system and automation solutions are used to ensure an extremely efficient process.

All in all, the high quality of the components and smooth running of the individual process steps are elementary for the Maltaria Campos Gerais plant. This is because the breweries have already planned several large orders in Brazil, which are currently ensuring full capacity utilization of the plant.

Sustainable management for environmentally friendly production

In addition to efficiency and profitability, sustainability is a high priority at Agrária. For this reason, the plant has heat exchangers to recover the heat generated in production. This achieves energy savings up to 20 percent. In addition, the technology used reduces water consumption. Investing in the topic of sustainability primarily generates good partnerships internationally, as the customers - large global corporations - also place a strong focus on this topic. Cooperativa Agrária is listed with the Sustainable Agriculture Initiative Platform (SAI) and ranked with 20% Gold and 80% Silver level. SAI is committed to building a sustainable agricultural sector and emphasizes strong as well as secure supply chains.

Keywords

Source

BRAUWELT International 2022

Companies

- Zeppelin Baumaschinen GmbH, Garching, Germany