Dual use | About two million tons of wet brewers’ grains come from German breweries every year. Traditionally, this is almost exclusively used as animal fodder [1]. However, in the wake of restructuring in agriculture and corporate amalgamations in the food sector, with an associated rise in waste from the food sector, such use is becoming increasingly problematic [2]. New recycling routes have thus to be found. Recovery of energy from the high organic content in brewers’ grain is of particular interest.

As in previous years we would like to demonstrate how the contribution of hop oils to beer can

At the AGM of the Maltsters’ Association of Great Britain (MAGB) on November 4th, the Association Chairman, David Wilkes of Boortmalt, highlighted the important work undertaken by the MAGB.

The 2014 Hopsteiner Guidelines are ready and will be available at BrauBeviale 2014 in Nuremberg.

Murphy & Son Ltd, Nottingham/UK have published a malt menu where they list their available products classified by formats (whole malt or crushed malt), type, available pack size and manufacturer.

The Hopsteiner Sensory Panel is dedicated to evaluating experimental hop varieties using quantitative descriptive analysis techniques. In addition to green hop and raw hop aroma evaluations, the sensory Panel also evaluates hop aroma and flavor in beer. Throughout the year, multiple beers are brewed using experimental varieties to gain a better understanding of overall hop impact on the final product. Included below are the initial tasting results from single hopped pale ales featuring an experimental variety that was used for three separate additions during brewing.

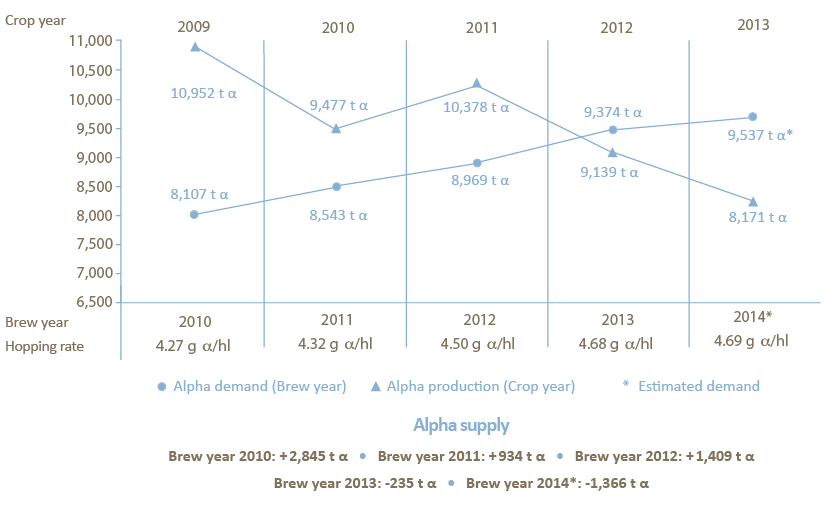

The Barth Report Hops 2013/2014 shows a slight deficit in the 2013 brewing year (2012 hop crop) after four years with large alpha surpluses.

Estimates for the 2014 hop crop in Germany were finalized in the Hallertau on August 20th. We are pleased to attach a list comparing the crop results for 2013 with the estimates for 2014 for the world’s main growing areas.

On April 1st 1964, Professor Dr. Ludwig Narziß was appointed as successor to Professor Dr. Karl Schuster at the Chair for Brewing Technology I. Simultaneously, he became the head of the Bavarian Teaching and Testing Pilot Brewery. Dr. Karl-Ullrich Heyse, honorary member of the Association of Alumni of the Weihenstephan University Brewing Department [EV] (VeW) and publisher of BRAUWELT International, held a short laudatio on the occasion of the general meeting of the Association in Frankfurt on May 24th, 2014.

At the Hopsteiner Forum in July 2014 a selection of Pale Ales were presented to an audience of brewers and brewing scientists to show the impact on beer aroma by only using different hop varieties for dry hopping. Unique and partly new hop varieties were selected to produce four single hopped beers and in addition four mixed combinations. The base beer of all eight Pale Ales was identical (14°P, 6% abv.) and exclusively made using

On 10 July 2014, the new edition of the Barth Report Hops 2013/2014 was presented to the trade press in Nuremberg. The Barth Report has a long tradition: no other hop company has reported more on hop cultivation and yield, supply and demand or breeding development and alpha acid production than the company from Nuremberg.