New method of sterilizing preforms eliminates the need for rinsing

With its new method of sterilizing preforms in advance, KHS now eliminates the need for classic upstream PET bottle sterilizing and rinsing. The significantly smaller area of the preform to be sterilized compared to that of the PET bottle surface reduces the required amount of sterilant considerably. This contributes not only to saving the cost of investment in a rinser but also saves rinse water.

The KHS method of preform sterilization is intended for use in the stretch blow molder/filler monoblock where a newly developed sterile chamber module has been implemented in the heater area.

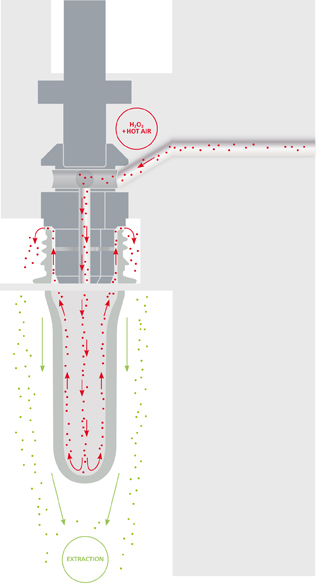

The sterile chamber module follows the initial preform heating process. A sterile air airlock reliably separates the sterile chamber at the preform feed end as well as the discharge end from the remaining heater area. This has the advantage of keeping germs from entering the heater area and at the same time ensuring that no hydrogen peroxide (H2O2) leaves the area of the heater. The risk of corrosion in the adjacent machine areas and hazards for machine operators from an increased amount of H2O2 discharged to the surrounding area are eliminated right from the start.

The preforms are sterilized inside the sterile chamber module by a mixture of hot air and hydrogen peroxide and are subsequently flooded with sterile air to reliably remove any remnants of H2O2that may still be clinging to the outside of the preforms. Once the sterilization process is completed, the preforms are conveyed to another heating chamber where an exact heating profile is applied to preheat the preforms quickly and particularly precisely. This enables best possible distribution of materials throughout the PET bottles during the stretch blowing process thereby producing especially lightweight PET bottles.

The preforms are transferred to the blowing process through a housing containing sterile air to eliminate any risk of contamination during transfer. The freshly blown PET bottles pass through the same kind of housing at the discharge of the stretch blow molder to ensure that the PET bottle materials are sterile when they ultimately reach the ultra-clean filling area through a sterile air airlock.

Source

BRAUWELT International 2011