Unlocking Mother Nature’s sublime packaging

Magpie&Marten | Dear readers: The following discussion continues one that began in our previous column in the print edition of BRAUWELT International, which is about the rising gelatinization temperature in barley.

As mentioned earlier, the authors of the book The Other Double Helix compare how starch and DNA store enormous amounts of energy and information, respectively (and hydrophobically), in a tiny space. Mother Nature is so adept at curling and coiling her sunlight-fueled reserves into tightly wound spirals that they can be stored for a long time and are difficult to disentangle.

During barley growth, starch biosynthesis commences at the hilum, the center of the granule, and eventually extends in a radial pattern outward towards its outer edge. The ways in which this occurs can differ across barley varieties. Chains of α-glucans are made of long polymers of glucose in its ring form (D-glucopyranose). Amylose develops into unbranched, long, single helices of α-1,4-linked glucose molecules, referred to as ‘linear’ or ‘straight’ chains. Amylopectin possesses a higher molecular weight and consists of glucose molecules also linked by α-1,6 bonds. Each α-1,6 bond forms a branch on the ‘straight’ chain.

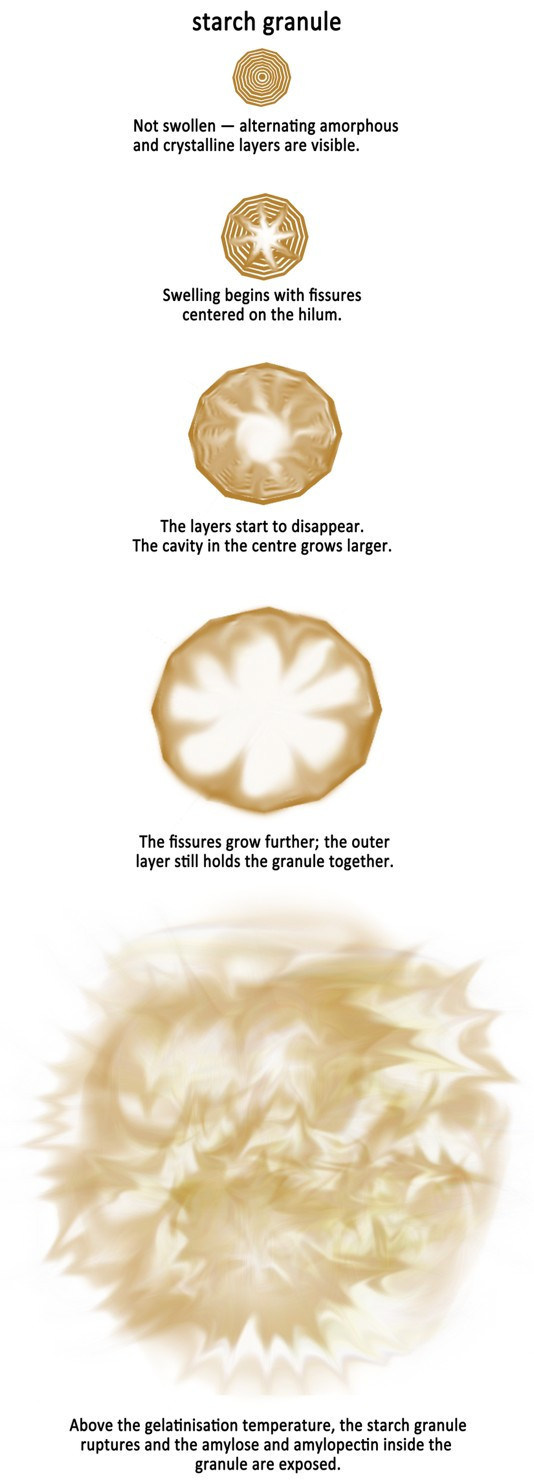

As growth and development continues, that is, as the barley enzymes are vigorously synthesizing starch, the single helices in the amylopectin begin to form double helices and become so dense that they crystallize. The nature of these molecules, hidden behind robust, resilient husks among other layers of protection, generally keeps creatures, microbial or otherwise, at bay who might be probing around for nutrients, causing them to ignore the largely inaccessible, almost indigestible substances. Between the crystalline layers, less dense amorphous layers develop so that ring structures similar to tree rings form. Mother Nature clandestinely and sublimely packages sunlight, carbon dioxide and water as storable energy into helices radially organized to create round granules.

Gelatinization in barley dependent upon regional climate conditions

And Mother Nature’s secret, only fire can tell, meaning that heat, combined with water, is required to unwind the starch. In their fiery, steaming kettles and tuns, brewers are able to unravel Mother Nature’s starchy convolutions…but this is changing. It almost seems that in her anger at our treatment of the Earth, she is twisting her already rigidly wound nutrients ever tighter to make them even less accessible. And since the Earth is running a fever, barley is more often cultivated in hot weather. Gelatinization temperatures rise as a result of hot growing conditions, especially if the heat remains constant during cultivation, above 25 °C, day and night. This means that the onset temperature required in an aqueous suspension/solution, like a brewer’s mash, to unlock the crystalline layers of the starch granules in malt is higher than it normally would be under more agreeable growing conditions. Therefore, gelatinization in barley is dependent upon regional climate conditions and thus varies year to year.

The authors were able to discuss this issue with maltsters at the drinktec just last week. UK maltsters, whose barley comes from the milder climate of the British Isles where many brewers employ a single step infusion at around 65 °C, seemed less concerned with the gelatinization temperature of their malt. Brewers on the Continent and in Scandinavia have not been as sanguine, having recently had to deal with significant increases in this important yet often ignored parameter. Interestingly, the gelatinization temperature seems to be independent of other parameters, like protein content. Maltsters are unfortunately powerless to effect any change in the gelatinization temperature.

Gelatinization behavior is characterized as ‘onset temperature,’ i.e., the beginning of the thermal transition to granule disintegration, and ‘endset’ or ‘conclusion temperature’ when water has been absorbed into the now swollen granule and the crystalline structure has been lost. A peak occurs between these two which is influenced by the amount of water available as well as the structural relationships between the amorphous and crystalline layers within the granule. These temperatures are determined by the distributions and lengths of the branched chains of amylopectin. They rise as the lengths of the branched chains in the amylopectin increase. The swelling of starch and the resultant surge in viscosity during mashing are mainly brought about by amylopectin. The onset of pasting describes the rapid increase in viscosity that occurs above the gelatinization temperature. In heating an aqueous suspension/solution of malt grist towards the endset temperature, the viscosity peaks and subsequently declines.

Without gelatinization, brewers cannot expose the starch they want to degrade to the amylolytic enzymes innate in the barley kernels. Given that the onset temperature for gelatinization can be above the optimum temperature range for the maltose rest, i.e., for β-amylase, this can be problematic. For this reason, climate change is forcing brewers to become more flexible in their brewhouse operations through the introduction of new procedures, such as supplementing their mashing processes with exoenzymes or altering their mashing regimes. Some may even feel the need to modify or otherwise rethink their brewhouse equipment, especially if the brewhouse is only furnished with a mash-lauter tun. Of course, for brewers working with adjuncts (i.e., not 100% barley malt) or for those able to use thermostable exoenzymes, this is less of an issue. For those operating within the realm of the Reinheitsgebot, some rather convoluted mashing regimes may be required to adequately uncoil their convoluted malt starch.

We’d like to hear what you think! Write to us with your thoughts, observations and/or opinions at .

Keywords

malt mashing brewhouse climate change gelatinization temperature

Authors

Nancy McGreger, Christopher McGreger

Source

BRAUWELT International 2025