Bitterness measurement with CDR BeerLab®

Beer bitterness mainly comes from α-acids in hops, which convert to iso-α-acids during boiling. This transformation is affected by factors like pH, time, and gravity. Bitterness is measured in International Bitterness Units (IBU), a standard used especially in industrial brewing for quality control and consistency. While IBU provides a technical measure of bitterness, its relevance in craft brewing is debated, as taste perception also depends on aroma, alcohol content, and individual sensitivity. Despite criticism, IBU remains a valuable tool for recipe design and is essential in both craft and industrial contexts, though for different purposes.

Bitterness in beer is primarily due to iso-alpha acids, but other factors like alcohol content, residual sugars, and roasted malts also influence taste. The official IBU definition, as given by the American Society of Brewing Chemists (ASBC), is:

IBU = A ~(275 nm)~ × 50 Equation 1

Where A (275 nm) is the absorbance at 275 nm of an acidified beer sample extracted with iso-octane. This measurement correlates properly with perceived bitterness, reflecting the presence of light-absorbing compounds which contribute to the bitter taste.

In craft breweries during the stage of recipe design and production planning, bitterness is often predicted using formulas like this one:

IBU = (AA% × W × U × 10) / V Equation 2

Where AA% is the alpha acid content of the hops, W is their weight, U is the utilization factor (affected by boil time, wort gravity, and hop form), and V is the volume of wort. While prediction tools are still used in brewing softwares, they cannot take into account all variables so the forecast can be valuable but not sufficient. To ensure quality and consistency, actual IBU quantification through analytical methods remains crucial.

The official analytical procedures are established by the American Society of Brewing Chemists (ASBC), the European Brewery Convention (EBC) and Mitteleuropäische Brautechnische Analysenkommission (MEBAK). These standardized methods are broadly adopted in both industry and research.

- UV Spectrophotometric Method – ASBC Beer-23A / EBC 9.8 / MEBAK III 2.21.2: Iso-α-acids are extracted from acidified beer using isooctane. The extracted absorbance at 275 nm is measured, and the IBU is calculated multiplying by 50, as previously cited. Though widely used, this method requires large volumes, manual handling, and may detect other interferents such as polyphenols.

- High-Performance Liquid Chromatography (HPLC) – ASBC Beer-23C: HPLC allows precise detection of specific iso-α-acids using UV detection at 270–275 nm. It is more accurate but requires specialized equipment and technical expertise, making it less accessible for small-scale use.

Alternative analytical methods: CDR BeerLab®

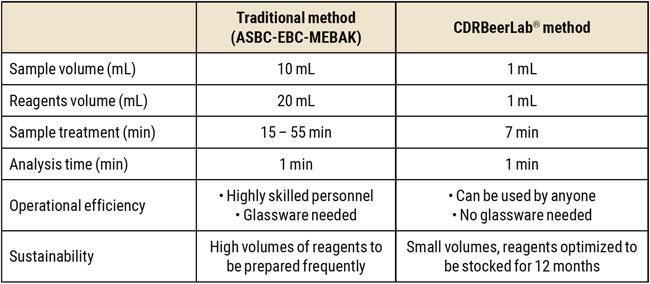

CDR BeerLab® offers a faster, simpler, and safer alternative to traditional IBU analysis methods. Based on a modified spectrophotometric technique, it measures iso-alpha acids at 270 nm with minimal sample preparation and delivers reliable results in just 5–6 minutes—significantly faster than the 15 to 55 minutes required by official methods. The system requires only 1 mL of sample, drastically reducing waste and allowing for multiple tests on the same working session. Its ease of use, thanks to pre-filled reagents and an intuitive interface, eliminates the need for specialized personnel or complex lab equipment. CDR BeerLab® can be used directly in the brewery, allowing real-time quality control during production or recipe development. It also offers environmental benefits due to lower reagent consumption and minimal waste production. In addition to IBU, the system can measure other key brewing parameters such as ABV, FAN, fermentable sugars, and VDKs, allowing a complete internal quality control protocol. Finally, its low operational costs make it a practical and economical solution for both craft and industrial breweries.

Finally, its low operational costs make it a practical and economical solution for both craft and industrial breweries.

Correlation study: some data from CDRBeerLab® performances

To validate the analytical performance of the CDR BeerLab® system in quantifying bitterness, a correlation study was conducted by the CDR Chemical Laboratory. The goal was to compare the results obtained using the CDR BeerLab® method with those from the official reference method EBC 9.8, widely recognized for the spectrophotometric determination of IBU.

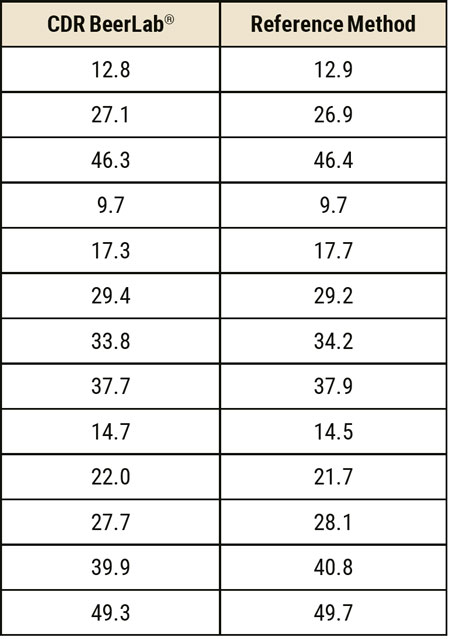

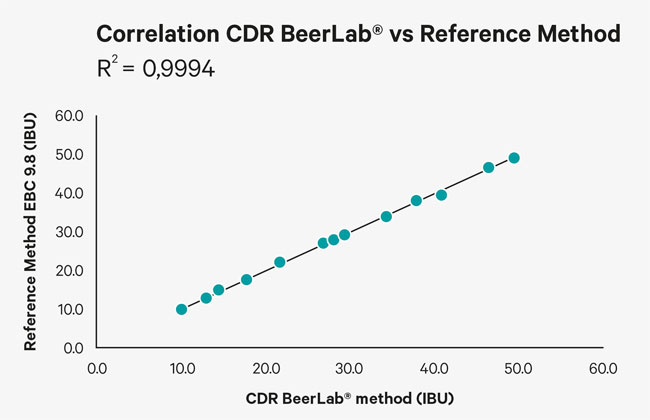

A series of beer samples with varying bitterness levels were analyzed using both methods. The resulting data showed a high degree of linear correlation, as illustrated in the graph below, with a coefficient of determination R² = 0.9994. This value confirms the excellent agreement between the two methods, demonstrating that the CDR BeerLab® provides highly reliable and consistent results in line with the official standard. In table 2 you find a comparison of CDR BeerLab® IBU method versus the standard spectrophotometric method EBC 9.8.

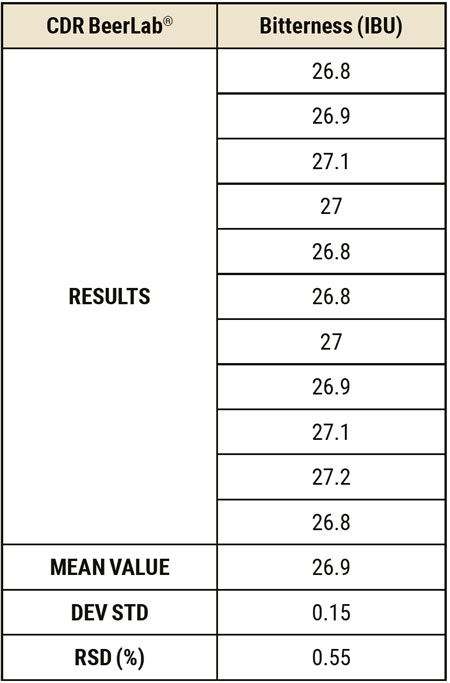

Table 3 reports the repeatability test: the measurement was repeated several times on the same sample to show the analytical response. The low RSD found, about 0.55%, indicates excellent repeatability of the method, demonstrating that the instrument provides highly consistent results under the same test conditions. The minimal variability among the replicates confirms the robustness and reliability of the measurement procedure. These experimental findings support the use of CDR BeerLab® as a valid and accurate tool for routine IBU measurement, particularly in settings where ease of use, speed, and low sample volume are operational priorities. On the other hand, CDR BeerLab® has already been using for many craft breweries and big brewing corporates worldwide.

Conclusions

CDR BeerLab® represents a fast, user-friendly, and reliable alternative for IBU analysis compared to traditional methods. It drastically reduces sample and reagent volumes, shortens analysis time to just a few minutes, and eliminates the need for complex lab equipment or highly skilled personnel. The system enables real-time quality control directly in the brewery and supports multiple brewing parameters beyond IBU. A correlation study against the official EBC 9.8 method confirmed its high accuracy (R² = 0.9994), validating its use for routine, efficient bitterness monitoring in both craft and industrial contexts.

References

- Boondocks Beer: Boondocks Beer. Brewers Corner: Hops. Available at www.boondocksbeer.com/brewers-corner/hops

- MEBAK Brautechnische Analysemethoden 4th Edition 2002, Volume II, Method 2.18.1, page 114ff

- ASBC Methods of Analysis, online. Beer-23, Beer Bitterness, A. Bitterness Units-Manual Isooctane Extraction [Release date 1968, revised 1975].

- European Brewery Convention. Analytica EBC, Method 9.8: Bitterness of Beer. Nürnberg: Fachverlag Hans Carl.

- American Society of Brewing Chemists. Methods of Analysis, Beer-23C: Iso-Alpha Acids by High-Performance Liquid Chromatography. St. Paul.

Keywords

hops bitterness measurement technology

Source

BRAUWELT International 3, 2025, page 152-153

Companies

- CDR Foodlab "Francesco Bonicolini", Florenz, Italy