Optimization of kettle hopping prior to dealcoholization

Technical Support | Non-alcoholic beers (NAB) are more popular than ever. Depending on the production technique of dealcoholization, NABs have a very different character. The state-of-the-art physical echniques to produce NABs are either thermal evaporation or reverse osmosis, besides the other technique of using speciality yeasts. For NABs produced by physical techniques, the sensory contribution of hops is even more pronounced after dealcoholization. Hop variety, hop product and hopping recipe can strongly influence the overall impression of the so produced NAB.

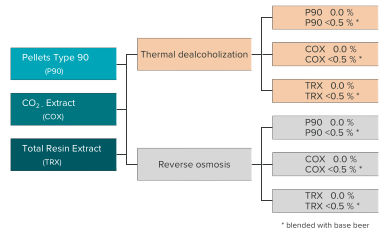

In cooperation with TU Munich (Chair of Brewing and Beverage Technology) we conducted a study to compare conventional kettle hop products used for the bittering during wort boiling and evaluated the taste on the corresponding NAB produced. The question to be answered: Which hop product is best suited for kettle hop addition in the base beer when producing a NAB lager beer using common physical dealcoholization methods? 12 NABs were made with 3 different kettle hop products, 2 different physical dealcoholization methods and 2 different final ABVs (0.0 and 0.5%), see figure 1.

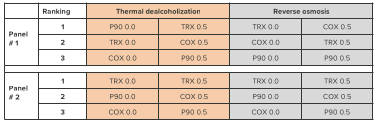

The sensory ranking of each NAB, based on the overall tasting results of two trained panels, are summarized in table 1:

Summarizing the tasting results, it can be concluded that compared to pellets, both types of hop extracts (Total Resin and CO2 Hop Extract) showed sensory advantages in the corresponding NABs produced.

Please find many more details and further performed analytical evaluations here.

Hopsteiner Newsletter April 2024 (PDF)