Plant-based, sustainable fining and foam control solutions

Plant-based brewing solutions | Natural plant-based brewing solutions represent a rapidly growing requirement for producers and consumers alike, with brands shifting focus toward using more versatile brewing ingredients that sustainably enhance process efficiencies while still delivering great tasting beer. Why? Attribute it to emerging younger consumers such as millennials and “Gen Zers,” two groups that identify as plant-based supporters in far greater numbers than older age groups. However, the cost advantages of sustainable plant-based solutions appeal to all age groups.

The vegan beer market has been growing at a CAGR of 33% over the last 3 years, according to Innova Market Insights 2023. This is driven by two demographic groups who place greater importance on factors such as sustainability and “naturality,” while also seeking to understand the origin of the food and beverage products they consume. Millennials (aged 26–41), for example, are twice as likely as baby boomers to say they’ve adopted a vegetarian or vegan diet. Gen Z (born between 1997 and 2012) is a demographic even more invested in a plant-based, sustainable future. In a 2022 consumer survey conducted by McKinsey & Company, 87% of Gen Zers were interested in buying plant-based alternatives. These beliefs are ingrained in their identity, and they display a consistent commitment to purchasing more natural, sustainable products.

Overall, consumers benefit from a “feel good” factor when they purchase sustainable products, and it’s a state of mind that shows no signs of abating. Kerry’s Consumer First study revealed that 83% of consumers would consider the environment when making a purchase. Quite simply, consumers want to do something for the environment and to fight global warming, so a strong focus on sustainability can be a key differentiator for regional beermakers in today’s ultra-competitive environment and a necessity for larger breweries that have made strong public commitments to their sustainability goals.

Brewing-industry supply prices – not only for ingredients such as barley, hops, labor and other inputs such as energy and water, but also upstream (raw material packaging) and downstream (bottles, kegs, cans, etc.) – continue to rise steadily. Globally, breweries are raising their prices in attempts to cover these escalating costs. This impact on consumer pricing has added steam to the search for avenues by which to cut costs, optimize production efficiencies and sustainably increase production capacity, all while remaining in step with ever-evolving consumer demands.

Natural, sustainable beer brewing is a growing trend, with breweries adopting new, innovative technologies that improve efficiencies and can be added seamlessly into a variety of process types, e.g., traditional or cross-flow membrane filtration, traditional fining or centrifugation, etc. These align easily and closely to the developing requirements of younger consumers, a group especially conscious of what they consume and the sustainability of those products. These are young people who are often forming brand loyalties today that will last a lifetime. That’s why many large brewers are committing to producing 100% sustainable plant-based beverages in the future. It’s a trend that will only accelerate as large breweries have long since committed to clear goals around sustainability, reducing their environmental impact, and increasing their process efficiencies.

Traditional processing aids in brewing

While most beer ingredients are vegan-friendly, the ones that are still animal-based perform valuable functions. Pepsin is one of the processing aids and compounds used in beer production; a foaming agent, it’s obtained from the stomach enzymes of pigs. Chitin, from lobster and crab shells, and carmine, found in the crushed scales of cochineal insects, are others.

These processing aids are very successfully used in beer production during the filtering process, making the beverage clearer and brighter while delivering valuable process efficiencies, time and cost savings. A beer with elevated haze may deteriorate more quickly, so fining agents are used by breweries to increase the brightness and clarity of finished beer by removing suspended yeast and haze-forming proteins and polyphenols. “Clearing” is an aesthetic and stability process that improves finished product appearance and provide more stability than a cloudier beer. This fining process also reduces costs by shortening aging times through removing excess, flavor-destabilizing components from the finished beer.

Below, we describe two new innovative, sustainable and plant-based brewing solutions available for use in alternative brewing processes or where plant-based is preferred over traditional chemical-based products.

Plant-based fining

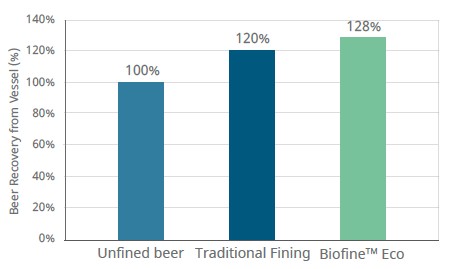

Kerry’s Biofine™ Eco is an innovative allergen-free, plant-derived clarification aid that has been developed as an alternative to traditional clarification aids. It significantly reduces maturation time leading to higher throughput, reduced energy consumption, and faster turnaround times. The beer itself benefits from immediate flocculation of yeast and trub by producing a compact sediment, reduced turbidity and significantly improves beer recovery by over 20%. This equates to enhanced product quality and stability in line with traditional clarification aids. Additionally, Biofine™ Eco has no impact on flavor or foam stability.

Plant-based foam-control

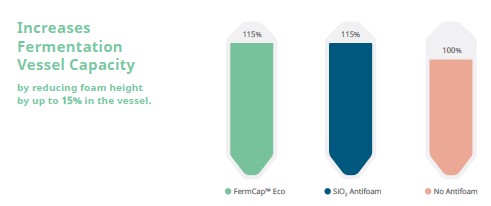

FermCap™ Eco is a patent-pending processing aid that has been developed to provide an alternative foam control solution, in particular where crossflow membrane filtration is used. It greatly reduces beer filtration time in membrane filtration systems and delivers consistent flux rates. This plant-based antifoam increases fermenter capacity significantly by up to 15%, thereby optimizing the capacity of the current brewery without any additional capital investment or process modification. It also improves hop utilization up to 10%, thereby reducing the dosages needed to give the required impact in the final beer. Additionally, this foam-control product also works to improve foam stability in the final beer, by having a positive protective effect on the foam-positive proteins that are naturally present in beer, but negatively impacted by over brewing process.

There are other logistical and operational benefits such as ease of cleaning (reduced CIP requirements) compared to chemical-based antifoam products. It is also freeze-thaw stable, allowing ambient shipping and storage all year around. FermCap™ Eco also maximizes CO2 recovery and reduces expensive wort losses.

Importantly, this new processing aid enhances beer quality by improving foam stability and having no impact on the foam-positive proteins that help ensure a tasty beer – both noteworthy benefits. In fact, a tasting panel of this plant-based antifoam processing aid found no impact whatsoever on beer flavor for bottled beer over its typical shelf life. Overall, FermCap™ Eco greatly reduces beer filtration times, delivering a 57% reduction versus untreated beer and a still-valuable 25% reduction versus the traditional SiO2 antifoam-treated beer.

Given the growth of natural and sustainable brewing solutions, both products – BioFine™ Eco and FermCap™ Eco – are timely and invaluable cost-effective tools for the growing number of breweries seeking to produce beer more sustainably.

For alcoholic beverage companies exploring future growth prospects and hoping to attract more brand loyalty, innovative tools will be one of the great differentiators. Ensuring your beer products are natural and that they contribute to the sustainability journey – a path that is exponentially growing in importance across competitive beer markets – is the challenge and the opportunity facing all beer brands. It’s clear that being seen as a leader in this journey is essential to conducting business today.

Keywords

processing aids beer foam Ireland product news plant-based products clarification

Source

BRAUWELT International 2023

Companies

- Kerry Group, Ireland